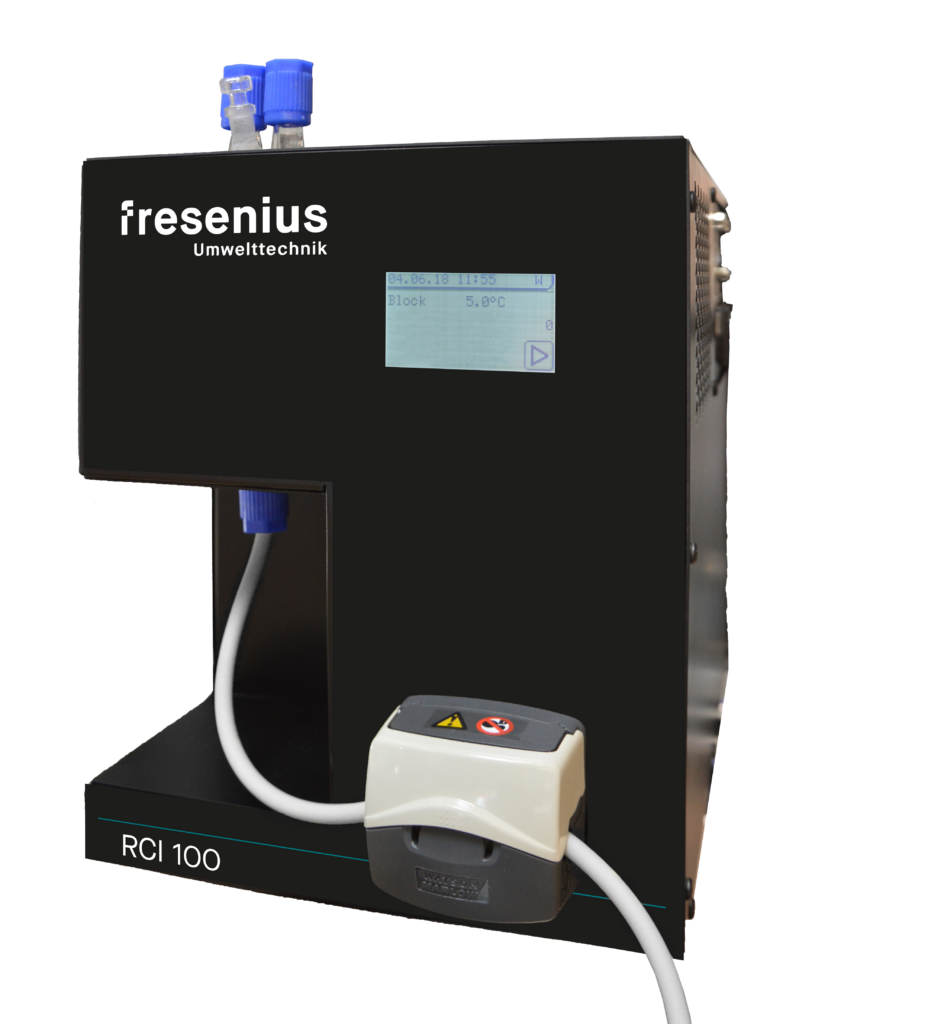

Front view

Gas Cooler RCI 100

The Gas Cooler RCI 100 reduces the humidity in the gas flow and precisely lowers the dew point. This protects your analysis devices from condensation damage and ensures reliable measurement results.

The Gas Cooler RCI 100 offers you a reliable solution for the effective removal of moisture from gas samples and comes in a wall-mounted or floor-standing housing. Thanks to its compact housing format, it is particularly versatile and can be easily integrated into existing infrastructure. By efficiently drying the gas samples , the RCI 100 reliably protects your analysis devices from corrosion and contamination, extending the service life of the devices and reducing maintenance costs.

The RCI 100 gas cooler impresses with its powerful functions and ease of use:

- Long-term stable and adjustable block temperature, which ensures constant cooling performance even under demanding conditions.

- Highly effective thanks to intelligent cooling regulation in conjunction with a temperature sensor, which ensures optimum drying even at high gas flow rates.

- Easy maintenance The heat exchanger is made of durable Duran glass and can be easily removed for cleaning.

- Temperature and humidity monitoring to regulate the cooling capacity and control the condensate separator

The Gas Cooler RCI 100 has a wide range of applications in various industrial plants. Typical areas of application include

- Chemical industry: For monitoring production processes where clean and dry gases are required for accurate analysis.

- Refineries: For monitoring gases in oil and gas processing.

- Recycling plants: Especially in refrigerator recycling plants where chlorofluorocarbons (CFCs) are measured.

- Asphalt industry

- Residual moisture: 0.86 % by volume at a dew point of 5 °C for precise and constant gas analyses

- Maximum gas flow rate: 260 l/h, ideal for high volume flows

- Cooling capacity: Up to 90 kJ/h, ensures effective removal of moisture

- Dimensions: 225 x 280 x 305 mm - fits into even the smallest installations.

- Weight: 13.2 kg

- Interfaces: RS232, Profibus DP, Modbus TCP, Ethernet IP, Profinet

- Long-term stable block temperature: controllable and reliable, even under demanding conditions

- Ready for operation: In just 15 minutes at an ambient temperature of 20 °C

- Easy maintenance: The heat exchanger is made of durable Duran glass and can be easily removed for cleaning.

Interactive 360-degree view

Advantages

Residual moisture

max. 0.86 vol.-% / dew point 5 °C / 41 °F

Operation

Simple operation via touch display

Ambient temperature

5 °C to 45 °C / 41 °F to 113 °F

Cooling capacity

max. 90 kJ/h

Flow rate

max. 260 l/h

Checking the dew point

Reliable gas analysis depends crucially on controlling the dew point. The Gas Cooler RCI 100 ensures long-term stability of the gas samples, regardless of the ambient conditions. This gives you the consistently accurate measurement results that your systems depend on.

Maximum moisture reduction

Our expertise guarantees maximum moisture reduction while minimizing the washout effect to ensure precise and reliable measurement results.

Versatile use in various industries

Whether in the pharmaceutical industry, recycling plants or refineries – gas coolers such as the RCI 100 are indispensable wherever precise measurement results are required with a high moisture content in the sample gas flow. With its robust construction and modular design, it simplifies maintenance and ensures that your processes run smoothly.

Optimized performance and lower maintenance costs

Thanks to the minimization of residual moisture to just 0.86% by volume, the RCI 100 protects your sensors and analysis devices from contamination and damage. This leads to a longer service life of the devices, lower maintenance costs and minimized production downtime – which significantly increases the productivity of your operation.

FAQ

What is the difference between the RCI 500, RCI 700 and RCI 100 gas coolers?

- RCI 500: This gas cooler comes in a slide-in housing for a system cabinet and processes a sample gas flow. It is ideal for applications where effective cooling and drying of a gas flow is required.

- RCI 700: The RCI 700 also comes in a slide-in housing and is designed to process two sample gas flows.

- RCI 100: This compact gas cooler is designed for floor or wall mounting and is ideal if no system cabinet is required. It processes one gas flow.

All devices offer a maximum cooling capacity of 90 kJ/h and a volume flow of up to 260 l/h per sample gas flow.

What does the washout effect mean?

In measurement technology and gas conditioning, the washout effect refers to the undesirable washing out of gas components by moisture or liquids.

- Components can be washed out when moisture is removed.

- This can falsify the concentration of certain gases in the measured sample because they are partially removed or attenuated.

- This leads to inaccurate measurement results and can falsify the analysis.

Thanks to our expertise and effective drying of the gases, the washout effect can be minimized with our gas coolers so that the original gas composition remains as unchanged as possible and precise measurement results are achieved.

Which industries benefit from the RCI 500, RCI 700 and RCI 100 gas coolers?

These gas coolers are used in a variety of industries:

- Process industry

- Pharmaceutical industry

- Refineries

- Recycling plants

- Environmental analysis

- Laboratories

Gas coolers play a central role, especially in areas where precise measurements and gas conditioning are required.

How easy is it to maintain the gas coolers?

Maintenance of the gas coolers is simple and user-friendly. The heat exchanger is made of durable Duran glass and can be easily removed for cleaning purposes. There is also a peristaltic pump for condensate drainage, which is also easy to maintain. This guarantees a long service life and reliable operation.

How high is the residual moisture after cooling?

The residual moisture of the RCI 100, RCI 500 and RCI 700 gas coolers is only 0.86 % by volume, which corresponds to a dew point of 5 °C.

What interfaces do the gas coolers offer?

The RCI 500, RCI 700 and RCI 100 models have various modern interfaces for easy integration into existing systems:

- Standard: RS232 interface

- Optional: Profibus DP, Modbus TCP, Profinet, Ethernet IP

- Configurable analog outputs: 4-20 mA for a flexible application.

Is there a warranty on the gas coolers?

The gas coolers are "Made in Germany" and are subject to strict quality controls. You can rely on a long service life and reliable service. You can find out more about the warranty and after-sales service on our service page and via our contact form.

Is there service and support?

We offer comprehensive services for all gas coolers. This includes regular maintenance, the supply of spare parts and technical support. Contact the service department for a customized service agreement tailored to your requirements.

Well? Interested?

Contact us for comprehensive advice - holistic and solution-oriented.

We use cookies and similar technologies to store and/or access device information. With your consent, we and our partners may use this data for ads personalization, measurement, audience insights, product development, security and fraud prevention. Furthermore, Google will use your personal data, among other purposes, to deliver and personalize ads when you give consent on this site (see How Google uses data). Other providers and details on how they use your data can be found in our Cookie Policy. If you don’t consent or withdraw your consent, certain areas, features and functions may be affected. You can change or withdraw your consent anytime via the white button permanently displayed at the bottom left of your browser window.

Functional Always active

Preferences

Statistics

Marketing

Functional Always active

Preferences

Statistics

Marketing

- ←

- Contact us Contact us

- WhatsApp us!

- Mail us!

- Call now!