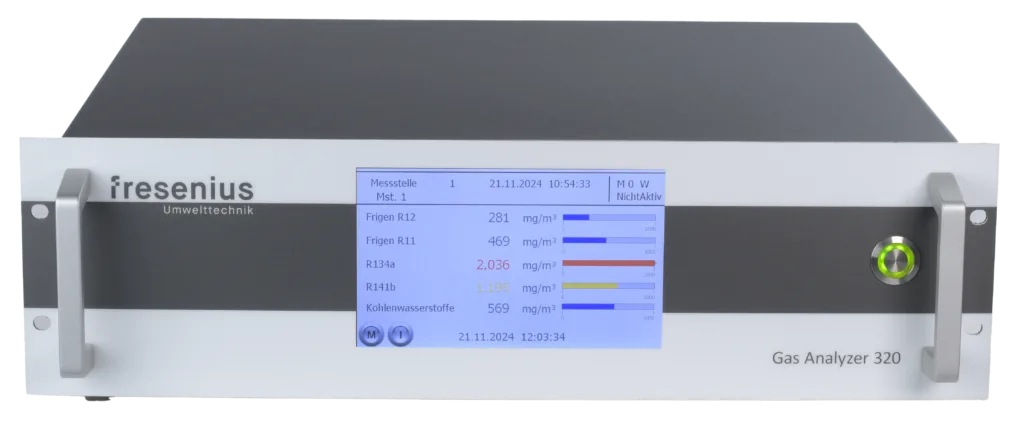

Front view

Back

Gas Analyzer 320

The Gas Analyzer 320 is the ideal solution for the analysis of up to 6 IR-active gases in a wide range of industrial processes. With its ability to detect the lowest detection limits and comprehensive cross-sensitivity compensation, it sets new standards in gas analysis. This stationary multi-gas detector has been specially developed for use in critical applications such as the measurement of greenhouse gases, frigenes and process control.

The Gas Analyzer 320 can be easily integrated into almost any of your industrial processes and meets both legal and safety requirements. Its precise measurement technology enables you to monitor greenhouse gases and frigenes as well as chemical and pharmaceutical processes. Thanks to its cross-sensitivity compensation, you can use this device in many possible applications and sample gas combinations. This allows you to avoid falsification of the measurement results due to interfering gases.

- Measure up to 6 gas components simultaneously with NDIR technology for precise results

- Cross-sensitivity compensation: This considerably increases the possible applications and sample gas combinations.

- Heated cuvette at 50 °C: Ensures stable values and prevents condensation.

- Integrated PC and 7-inch touch display: user-friendly menu and real-time data display.

- Automatic pressure compensation: Exact measurement results even under changing pressure conditions.

- Minimal maintenance: long-term stability and reduced calibration requirements.

- Wide range of communication interfaces: Profibus DP, Ethernet Modbus TCP, Ethernet IP, Profinet, up to 8 analog outputs (gal. Isolated)

The Gas Analyzer 320 is the ideal choice for various applications:

- Chemical engineering and environmental technology: Ensuring compliance with legal emission limits.

- Recycling and monitoring: control of gases in critical processes.

- Pharmaceutical industry: Precise measurements for process control.

- Quality control: Precise monitoring of gas mixtures for process optimization.

- Sample gas inputs/outputs: 1 (standard), expandable to up to 6 inputs, 1 output

- Measurement interval: 20 seconds

- Measurement technology: NDIR single-beam method, heated cuvette (50 °C).

- Internal pump: Standard 4 l/min

- Protection class: IP20

- Power supply: 230 V AC / 50 Hz or 115 V AC / 60 Hz.

- Weight: 16 kg

- Data communication: RS232, optional Profibus DP, Ethernet Modbus TCP, Profinet

Interactive 360-degree view

Advantages

Precision at the highest level

Thanks to NDIR measurement technology, the Gas Analyzer 320 provides you with extremely precise measurement results – even at low detection limits. The 50 °C Heated cuvette minimizes influences and guarantees reliable analyses even under demanding conditions.

Flexibility and simple operation

The 7-inch touch display enables intuitive operation and real-time data display. With up to 6 sample gas inputs and a wide range of interface options (RS232, Ethernet, Profibus DP), the device can be flexibly adapted to your process requirements.

Cost efficiency through low maintenance

With its long-term stable calibration and minimal maintenance requirements, the Gas Analyzer 320 significantly reduces your operating costs. The integrated pressure compensation ensures consistently accurate values without the need for frequent readjustments.

FAQ

What applications is the Gas Analyzer 320 suitable for?

The Gas Analyzer 320 is ideal for monitoring and analyzing process gases in chemical engineering, recycling, environmental technology, the pharmaceutical industry and for legally required emission measurements. It measures up to 6 IR-active gases precisely and with long-term stability, even under demanding process conditions.

How does the Gas Analyzer 320 save operating costs?

Thanks to the long-term stable NDIR measurement technology and automatic zero point correction, the device requires only minimal maintenance and infrequent calibrations. This saves time, test gas and service costs, significantly reducing the total cost of ownership.

How does the Gas Analyzer 320 improve the profitability of my system?

The Gas Analyzer 320 helps you to monitor your processes more precisely and control them more efficiently, allowing you not only to optimize product quality, but also to use raw materials more economically and with fewer resources.

How long does it take to put the device into operation?

The Gas Analyzer 320 is fully operational in just 30 minutes. Thanks to the plug-and-play design and intuitive menu navigation, installation and configuration are particularly easy.

Which gases can be measured with the Gas Analyzer 320?

The device measures up to 6 IR-active gases simultaneously, including greenhouse gases such as carbon dioxide (CO₂), carbon monoxide (CO), methane (CH₄) or carbon monoxide (CO).

You are welcome to send us an inquiry for other IR-active substances.

Contact us and we will talk about your individual configuration.

What interfaces does the GA 320 offer?

The GA320 is compatible with data communication interfaces such as RS232, Profibus and Ethernet so that it can be easily integrated into existing and future systems.

All available interfaces:

- Profibus DP

- Ethernet Modbus TCP

- Ethernet IP

- Profinet

- up to 8 analog outputs (gal. Isolated) 4-20 mA

What services does Fresenius Umwelttechnik offer?

We offer comprehensive service packages, including regular maintenance, fast repairs and on-site service. There is also the option of renting replacement devices to avoid downtime.

Well? Interested?

Contact us for comprehensive advice - holistic and solution-oriented.

Fresenius Umwelttechnik GmbH

Office hours

Time zone CEST

The company

Contact us

© 2024 Fresenius Umwelttechnik GmbH