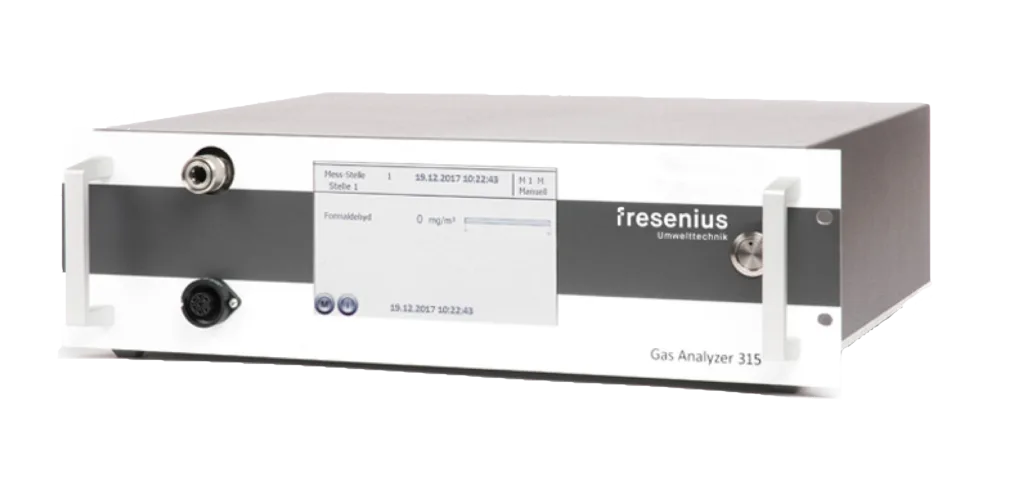

Front view

Gas Analyzer 315 Hot Gas

The Gas Analyzer 315 Hot Gas is a stationary hot gas measuring device and enables the online measurement of highly water-soluble substances at high humidity in hot exhaust gas streams. It is the only device with NDIR technology for hot gas measurements on the market and offers you a particularly economical solution.

The Gas Analyzer 315 Hot Gas was specially developed for the direct, loss-free measurement of IR-active substances in hot exhaust gas streams. The measuring device can be used to monitor combustion processes, for example to determine the formaldehyde content in the exhaust gas of gas engines in biogas and landfill gas plants. Thanks to the patented NDIR method with vacuum reference technology and the heated measuring cell, you can record your measurement data precisely and continuously even at high temperatures (up to 300 °C) and significant moisture content - without the need for an additional sample gas cooler, gas conditioning or sending gas samples to a laboratory.

- Loss-free measurement: Direct online measurement of formaldehyde and other water-soluble IR-active gas components, even at high temperatures and humidity levels.

- Economical measuring method: Patented NDIR method for hot gas measurement with vacuum reference technology and a heated cuvette (85 °C) ensures long-term stability with high measurement accuracy.

- Intuitive operation: A user-friendly 7" touch display (800 x 480 pixels) with plain text menu navigation and integrated Windows CE 5.0 R3 allows you to operate the device quickly and easily.

- Flexible data transmission: The open interface architecture ( RS232, Profibus DP, Ethernet Modbus TCP, Ethernet IP, Profinet and up to 8 analog outputs) can be optimally integrated into your existing process control system.

The Gas Analyzer 315 Hot Gas is versatile and can be used in a wide range of applications:

- Industry: Optimize production processes by precisely monitoring exhaust gases in incineration plants.

- Energy generation: Use the device in power plants and heating systems to efficiently control emissions.

- Waste management companies: Use the Gas Analyzer in biogas and landfill gas plants to record environmental data in real time.

- Monitoring: In environmental protection and monitoring stations, the device guarantees continuous analysis of pollutants.

- Engine manufacturers: Improve development processes and optimize exhaust gas properties through precise measurements in engine production.

- Emission measurements: Use the measuring device for the annually prescribed control measurement on gas engines to obtain results more quickly and to be able to reconfigure the gas engine immediately.

- Gas components: 1 x NDIR e.g. formaldehyde (CH₂O), ammonia ( NH₃) - (other substances on request)

- Measuring range: 0-200 mg/m³ / 0-160 ppm

- Measurement uncertainty: < 5 % of the measured value

- Detection limit: 4 mg/m³ / 3 ppm

- Sample gas flow rate: 4 l/min

- Pressure tolerance: 0.7 to 1.1 bar (process gas pressure)

- Climatic conditions: Ambient temperature 5° - 45° C /

relative humidity ~ 90 %, dew-free - Display: 7-inch touch display (800x480 pixels)

- Interfaces: RS232 Profibus DP, Ethernet Modbus TCP, Ethernet IP, Profinet, up to 8 analog outputs (gal. Isolated) 4-20 mA, freely configurable via display menu

- Power supply: 230 V AC / 50 Hz, 0.9 A / 207 VA

Alternatively: 115 V AC / 60 Hz or 230 V / 60 Hz - Dimensions: 19" rack, depth 400 mm

- Weight: 17 kg

Advantages

Precision and reliability under extreme conditions

The Gas Analyzer 315 is the only hot gas detector to use NDIR technology with patented vacuum reference technology, which enables drift-free and highly accurate measurement of formaldehyde. This technology eliminates typical sources of error such as zero drift and minimizes cross-sensitivities – without using test gases.

Cost efficiency due to low operating costs

With the GA 315 Hot Gas, you benefit from a significantly more cost-efficient solution than with conventional measurement methods. Thanks to online hot gas measurement, you receive immediate results without having to send samples to a laboratory.

Versatile applications in demanding conditions

The GA 315 is specially designed for the challenges of measuring formaldehyde (CH₂O) and other water-soluble sample gas components such as ammonia (NH₃) in hot gas flows up to 300°C. Its robust design, heated components and comprehensive correction procedures make it the ideal solution for measuring in hot exhaust gas streams.

FAQ

Why is the GA 315 Ganalyser unique on the market?

Fresenius Umwelttechnik is the only manufacturer to have developed an NDIR-based process that solves the challenges of formaldehyde measurement and other highly water-soluble measurement gas components at high dew points or high measurement gas temperatures. Measuring these components (e.g., formaldehyde (CH₂O), ammonia (NH₃)) is technically demanding, as high moisture content in gas streams complicates the measurement. At the same time, gas coolers cannot be used, as the substance would dissolve in the condensate.

Our design with heated components and mathematical correction methods enables precise and stable measurements at high humidity and high temperatures (up to 300 °C).

Who is the GA315 gas analyzer particularly suitable for?

The GA 315 Hot Gas is specially designed for applications in the field of hot gas analysis. Test institutes, engine manufacturers and operators of exhaust gas monitoring systems in particular benefit from the direct online measurement in the hot exhaust gas flow. The system delivers precise results even at high gas moisture contents and temperatures - and at a significantly lower price than conventional measurement methods.

What distinguishes the GA 315 Formaldehyde from conventional measuring methods?

The GA 315 Hot Gas uses a patented NDIR measuring method with vacuum reference technology that enables direct online hot gas measurement. Our technology eliminates the need for sample gas coolers. This has the advantage that water-soluble components such as formaldehyde (CH₂O) or ammonia (NH₃) are not washed out in the condensate, which leads to much more precise measurement results.

How quickly are measurement results available?

The device is ready to measure after just 5 minutes and reaches its full specifications within 30 minutes. This rapid operational readiness enables test centers to react promptly to measurement results and adjust gas engines directly.

What are the economic advantages of the GA 315 Formaldehyde?

Thanks to direct online measurement, measured values can be measured directly on site without having to wait for the results from a test laboratory. Gas engines, for example, can be reconfigured directly to the emission limit values. This saves you a lot of time, which makes the entire testing process considerably more cost-efficient. With the GA 315 Hot Gas, you reduce operating costs and enable rapid process adjustments.

In which industrial areas can the GA 315 Formaldehyde be used?

The measuring device is ideal for use in industrial areas such as exhaust gas monitoring in combustion processes, gas engine test benches, biogas and landfill gas plants as well as in energy generation and waste disposal. Test centers and engine manufacturers alike benefit from the fast and precise recording of emission values.

How can the GA 315 Formaldehyde be integrated into existing process control systems?

Thanks to its open interface architecture, which includes standard RS232 as well as optional interfaces such as Profibus DP, Ethernet (Modbus TCP, Ethernet IP) and Profinet, the Gas Analyzer 315 Hot Gas can be seamlessly integrated into existing control systems and process control systems. This ensures flexible and future-proof integration.

What are the dimensions and structural characteristics of the appliance?

The GA 315 Hot Gas has a compact 19″ slide-in housing with dimensions of approx. 482.6 mm (width) x 135 mm (height) x 400 mm (depth) and a weight of around 17 kg. This industrial design enables easy installation in existing systems and control cabinets.

What interfaces and communication options does the device offer?

In addition to the standard RS232 connection, the analog offers optional interfaces such as Profibus DP, Ethernet (Modbus TCP, Ethernet IP), Profinet and expandable analog outputs (4-20 mA).

How does online hot gas measurement work and what advantages does it offer?

The online hot gas measurement enables the direct analysis of the sample gas in the exhaust gas flow without the need for additional treatment, such as cooling or the use of a gas cooler. This prevents water-soluble components such as formaldehyde from being lost in the condensate and leads to accurate, fast and reliable measurement results.

Under what operating conditions does the GA 315 Formaldehyde work reliably?

The device is designed for operation in ambient temperatures from 5° to 45 °C and at relative humidity levels of up to approx. 90 % (dew-free). In addition, measurements can be carried out in the exhaust gas flow at temperatures of up to 300 °C and at high humidity levels.

How does the GA 315 Formaldehyde support testing laboratories in measuring emissions?

Test institutes benefit from the rapid availability of precise measurement results, which enable immediate adjustment and optimization of gas engines, for example. This makes the testing process more efficient and time-saving.

Well? Interested?

Contact us for comprehensive advice - holistic and solution-oriented.

We use cookies and similar technologies to store and/or access device information. With your consent, we and our partners may use this data for ads personalization, measurement, audience insights, product development, security and fraud prevention. Furthermore, Google will use your personal data, among other purposes, to deliver and personalize ads when you give consent on this site (see How Google uses data). Other providers and details on how they use your data can be found in our Cookie Policy. If you don’t consent or withdraw your consent, certain areas, features and functions may be affected. You can change or withdraw your consent anytime via the white button permanently displayed at the bottom left of your browser window.

Functional Always active

Preferences

Statistics

Marketing

Functional Always active

Preferences

Statistics

Marketing

- ←

- Contact us Contact us

- WhatsApp us!

- Mail us!

- Call now!