If you own or want to build a biogas plant, you are making a valuable contribution to renewable energy production. But how do you ensure that your plant works reliably, delivers an optimum methane yield and always meets safety and environmental requirements? The answer lies in precise gas analysis. By closely monitoring the composition of your biogas at all times, you can control your plant more efficiently, avoid breakdowns and reduce your operating costs. At Fresenius Umwelttechnik, we understand how important accurate and continuous online gas analysis is to the success of your biogas plant. That’s why we offer you advanced gas measurement devices that have been specially developed for the requirements of biogas processes – for maximum process reliability, efficiency and longevity of your plant, as well as compliance with environmental standards and legal requirements.

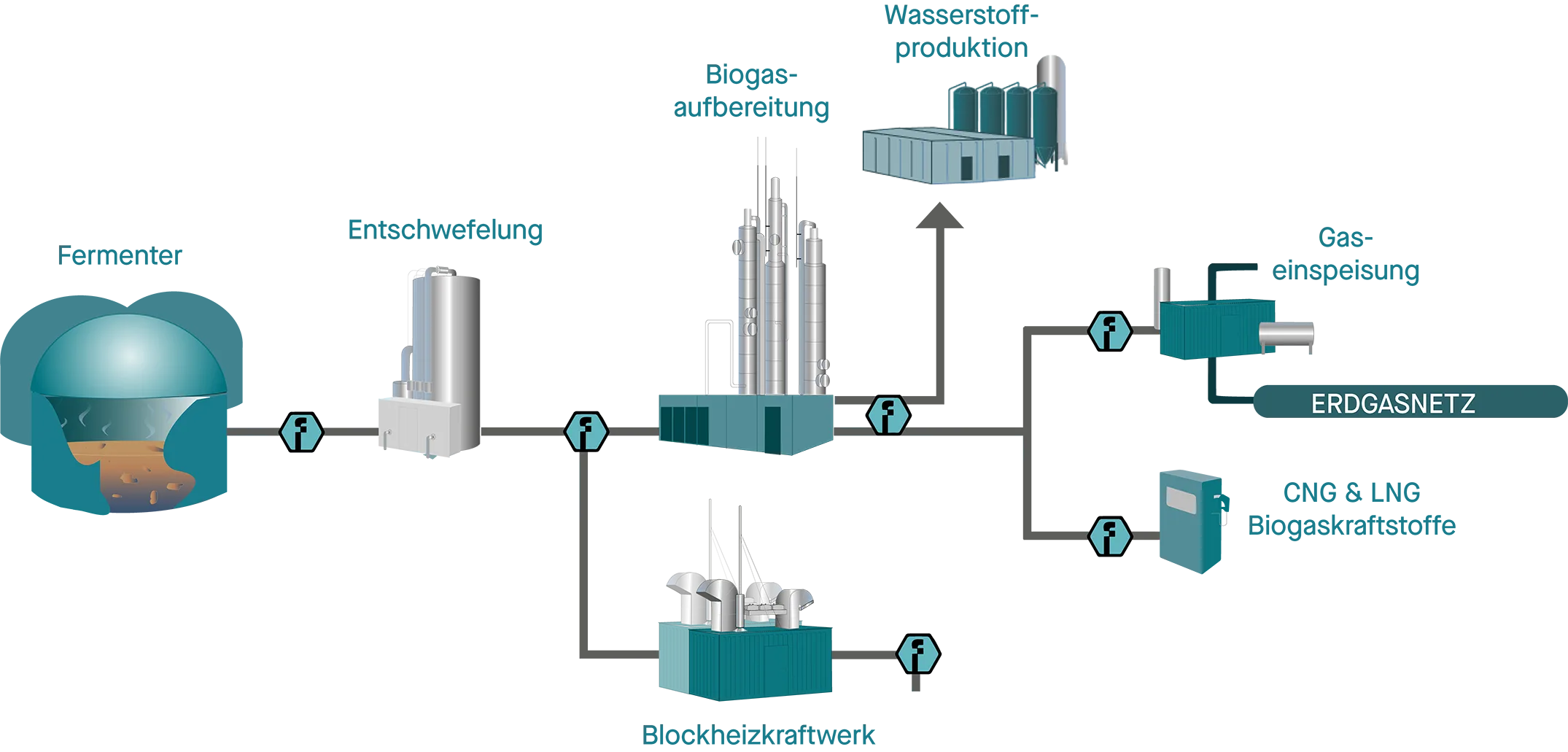

Interactive process graphic

Select a point on the graphic to find out information about the solutions for the respective gas tapping points below the graphic.

(The selection refers to the respective extraction point (eng. touchpoint) that would be suitable for your biogas plant)

Solution for the selected tapping point:

Biogas analysis between fermenter and desulphurization: Precise control of the gas composition

The gas extraction point directly after the fermentation process in the fermenter is an ideal point for monitoring the fermentation process. The resulting biogas is analyzed at this point in order to record key process parameters. The regular measurement of gas components such as methane (CH₄), carbon dioxide (CO₂), hydrogen sulphide (H₂S), oxygen (O₂) and hydrogen (H₂) provides valuable information about the condition and stability of the anaerobic fermentation. This allows deviations to be detected at an early stage and targeted measures for process optimization to be initiated.

The measurement of ammonia (NH₃) can also be integrated as an option. Recording the ammonia content provides additional insights into the microbial metabolism and the nutrient balance in the fermenter.

Other substances can also be monitored on request.

Our gas analyzers - such as the BioBasic - enable continuous online gas measurement directly in the process. With precise real-time data on the relevant gas components, you receive reliable monitoring that helps you to operate your biogas plant efficiently and safely.

Hydrogen sulphide monitoring

Hydrogen sulphide (H₂S) is one of the most critical components in raw biogas, as it has a corrosive effect and can cause damage to downstream plant components - for example in upgrading to biomethane or in gas engines, which must comply with strict limits. In order to effectively reduce the sulphur content in biogas, precise monitoring both before and after desulphurization is crucial. It is important to know how high the H₂S concentration is before the gas is fed into the desulphurization process and to ensure that the desulphurization process achieves the desired effect.

Only with precise H₂S monitoring can you guarantee that the treated biogas can be safely reused - whether for upgrading to biomethane, in a combined heat and power plant (CHP ) or in other industrial applications. This ensures that all downstream processes are optimally protected and the specified limit values are adhered to.

Our gas analyzers - such as the BioBasic and the GAP 100 - monitor the H₂S content at the crucial points. You receive precise, real-time data that helps you to efficiently control the desulphurization process and avoid potential damage to downstream plant components. The devices offer reliable, continuous online measurement that can be seamlessly integrated into your processes.

Catalyst monitoring for the GA315 Hot Gas

Formaldehyde (CH₂O) can be produced under certain conditions after the combustion of biogas in a combined heat and power plant (CHP). This highly reactive and carcinogenic pollutant is subject to strict legal emission limits. In combined heat and power (CHP ) plants in particular, it is crucial to precisely monitor the formaldehyde concentration to ensure compliance with legal requirements and protection of the environment.

Our GA315 formaldehyde was specially developed for the measurement of hot gases that occur immediately after combustion in CHP units. The device uses the non-dispersive infrared (NDIR) measuring method to reliably detect formaldehyde even at high temperatures and in very low concentrations in the ppm range. This enables continuous measurement directly in the exhaust gas flow, ensuring seamless monitoring and documentation of the emission values.

The GA315 Formaldehyde offers a long-term stable and low-maintenance solution that directly supports test institutes and engine manufacturers in carrying out emission tests to comply with legal limits.

Biomethane and CO₂ measurement after biogas upgrading

After biogas upgrading, precise monitoring of the biomethane content (CH₄) and CO₂ content is crucial for product quality and the economic value of the gas. A high methane content and a low CO₂ content improve the combustion properties of the biomethane, increase energy efficiency and reduce emissions - which leads to a higher energy yield and thus better returns.

The GA 220 (Gas Analyzer 220) enables the continuous measurement of methane (CH₄) and carbon dioxide (CO₂) using the non-dispersive infrared (NDIR) measurement method. This method ensures precise and long-term stable measurements of the two gas components. The purer the biomethane - i.e. the higher the methane content and the lower the CO₂ content - the more efficient the combustion and the higher the value of the processed gas.

With the GA 220, you ensure that the upgraded biomethane achieves the required purity and that your plant operates both safely and efficiently. This not only maximizes the product quality, but also increases the efficiency of your biogas plant.

Gas injection: Precise measurements with the biomethane TDLAS and effective sample gas conditioning

When feeding biomethane into the natural gas grid, precise monitoring of the methane concentration is crucial. After processing, methane concentrations of up to >99% by volume are expected at this point, which requires maximum accuracy.

The biomethane TDLAS measures methane (CH₄) with an accuracy of 0.01% by volume and overcomes the saturation effects that occur with conventional NDIR methods at high methane concentrations. Thanks to its laser-based technology, it detects specific absorption lines, making it ideal for measuring points with high concentrations.

Compact system solution: An equipment cabinet with the biomethane TDLAS allows precise methane measurements. If required, modules for monitoring other substances can be added.

Measurement before processing into biofuels, CNG and LNG: ensuring gas quality

When producing LNG (liquefied natural gas) and CNG (compressed natural gas), monitoring the gas composition is crucial. After processing, methane concentrations of up to >99% by volume are expected, while carbon dioxide (CO₂) and oxygen (O₂) must be kept within narrow limits to avoid crystallization (CO₂) and safety risks (O₂).

The biomethane TDLAS measures methane with an accuracy of 0.01% by volume and overcomes the limitations caused by saturation effects with NDIR in high methane concentrations. Modules with NDIR and electrochemical sensors can be added for monitoring CO₂ and O₂.

Efficient system solution

An appliance cabinet with the biomethane TDLAS and optional modules for CO₂ and O₂ measurement offers a precise and flexible solution. As the gas is already very pure, no additional gas coolers are required.

Featured:

BioBasic

For

- -methane

- -Carbon dioxide

- -Hydrogen sulphide

- -oxygen

- -Hydrogen

The power pack with up to 5 measuring points.

BioBasic

For

- -methane

- -Carbon dioxide

- -Hydrogen sulphide

- -oxygen

- -Hydrogen

The power pack with up to 5 measuring points.

GA315 Formaldehyde

For

Strict formaldehyde monitoring with low detection limits

Hot gas measuring device for compliance with strict emission limits.

Gas Analyzer 220

For

- -methane

- -Carbon dioxide

- -oxygen

Slide-in system without running costs.

Biomethane TDLAS

For

- -methane

The fastest and most precise continuous online measurement, at high concentrations without saturation effects with an accuracy of 0.01% vol.

Biomethane TDLAS

For

- -methane

The fastest and most precise continuous online measurement, at high concentrations without saturation effects with an accuracy of 0.01% vol.

Other suitable products for your biogas plant:

Gas Analyzer Portable 100

The Gas Analyzer Portable 100 (GAP 100) is a flexible, portable gas measurement system designed for field use. With the ability to precisely measure gases such as CH₄, CO₂, H₂S and O₂, the device is ideal for mobile spot measurements in biogas, sewage treatment and landfill plants.

Gas Cooler Series

Our gas coolers are essential components of sample gas conditioning and are used to significantly reduce moisture in gas samples. They ensure stable and reproducible measurement results by preventing condensation in sensitive measuring cells.

Smart Control 300

The SmartControl 300 is a cost-effective stationary NDIR measuring device developed for monitoring threshold concentrations in gas mixtures containing solvents. It is characterized by high long-term stability and low operating costs.

ExGard

The ExGard is an explosion-proof gas detector specially developed for monitoring toxic and flammable gases such as methane (CH₄), carbon monoxide (CO) and oxygen (O₂). It works in critical industrial environments and ensures maximum safety.

Custom Solutions

Every system has its own requirements – and we deliver the right solution. Whether compact system cabinets, customized integration into existing infrastructures or completely individual concepts: We develop solutions that are precisely tailored to your needs.

Our approach makes it possible to optimally combine high-performance gas analyzers and other process measurement technologies – whether in a centrally organized housing or through flexible integration directly into your existing system. You not only save space, but also benefit from a well thought-out structure that makes maintenance and operation easier.

These engineering services are complemented by our comprehensive service concept. If required, the components can be easily removed and sent in for maintenance – alternatively, our experienced service team is available to support you directly on site. This maintenance model guarantees minimal downtime and ensures the continuous operation of your system.

Your advantages

Maximum process reliability

Our gas analyzers ensure continuous and precise monitoring of your biogas production so that you are always in control of the process. Reduce the risks to your plant, protect your plant from premature wear and tear, ensure the quality of your production and monitor emissions in an environmentally conscious way to comply with regulations and ensure employee safety.

Optimized methane yield

Thanks to our high-precision gas analyzers, you can monitor the methane content in real time. This allows you to ensure that the minimum quality for feeding into the natural gas grid is achieved – a prerequisite for generating additional revenue. A higher methane yield means greater efficiency and higher profits, as you get more valuable biomethane out of your plant.

Protection of your system

With accurate H₂S measurement, you can protect your gas engines and catalytic converters from harmful corrosion. This not only reduces maintenance costs, but also significantly extends the service life of your system technology. With our gas analysis devices, you can minimize expensive repairs and unnecessary downtime.

Long-term cost reduction

Our appliances are designed for a long service life and minimal maintenance. This reduces the running costs of your system. Should maintenance nevertheless be necessary, we offer you rental devices so that your system can continue to operate without interruption. Investments in our measurement technology pay off quickly – through optimized processes, reduced operating costs and higher yields.

All-round service

With our on-site service and the option to easily send in devices for maintenance, you can always be sure that your biogas plant is running smoothly. Our service team is at your side so that you can concentrate on the essentials: efficient and economical production.

FAQ

Why is gas measurement technology even necessary in a biogas plant?

Measurement technology is essential for precisely monitoring and optimizing the gas composition in the biogas process. By continuously recording the methane concentration (CH₄), you can maximize the methane yield in a targeted manner, which makes a significant contribution to the efficiency of your plant. At the same time, monitoring the hydrogen sulphide content (H₂S) allows you to avoid potential corrosion damage to sensitive system components - a crucial factor in protecting your system from harmful influences.

In addition, the measurements of carbon dioxide (CO₂), hydrogen (H₂) and oxygen (O₂) concentrations provide important information about the fermentation process. This allows you to assess the state of fermentation and react to deviations at an early stage. The strategic placement of gas sampling points - for example directly after the fermenter or before and after desulphurization - allows you to monitor critical process steps in detail. This gives you a comprehensive picture of the entire plant.

How does process measurement technology contribute to the economic efficiency of my biogas plant?

Process measurement technology is the key to maximizing methane quality and optimizing the entire plant. Through the continuous use of modern gas analyzers, essential parameters are monitored at every stage of the process. This precise measurement enables the production of high-quality biogas or Biomethane with a higher methane content.

A higher methane content means that you can generate more energy from the same amount of gas. At the same time, the precise monitoring of hydrogen sulphide (H₂S) makes it possible to minimize wear on critical components such as gas engines and catalytic converters. This reduces operating costs and prevents expensive system damage.

With our advanced measurement technology, you benefit from:

- Continuous monitoring of the CH₄ concentration to ensure reliable production.

- Optimization of the fermentation process by monitoring all relevant parameters such as hydrogen (H₂) and oxygen (O₂).

- Minimization of corrosion risks through early control of the H₂S content, which reduces wear on important system parts.

How does the measurement technology support the safety of my biogas plant?

By continuously monitoring gas components such as hydrogen sulphide (H₂S), which has a corrosive effect and can damage motors, gas analyzers make a decisive contribution to the safety of your system. They help to detect dangerous concentrations at an early stage and take protective measures in good time, which ensures the longevity of the system.

In addition, the BioBasic, for example, has ATEX-certified flame arresters that protect your system from explosion risks. It also has internal LEL monitoring in the housing.

How does measurement technology protect my employees from hazardous gases such as formaldehyde (CH₂O)?

The safety of employees in a biogas plant is of central importance - especially with regard to gases such as formaldehyde (CH₂O), which can be produced during combustion in combined heat and power plants (CHP plants). Formaldehyde is a toxic gas that can irritate the mucous membranes even in low concentrations and is considered potentially carcinogenic in the event of prolonged exposure. Regular testing is therefore required by law to ensure compliance with safety limits and to protect both employees and the environment.

How often do the measuring devices need to be serviced?

Our gas analyzers and gas coolers are designed for a long service life and require little maintenance. As a rule, annual maintenance is sufficient to ensure measurement accuracy and reliability. If maintenance is due, we offer you loaner devices that you can use during this time. This ensures that your biogas plant remains in operation without interruption and your processes continue to run smoothly.

What happens if a component fails?

Should one of the devices fail, we offer you a quick solution: either through our on-site maintenance service or by sending you loan devices that you can use during the repair. This means that your system remains operational at all times and there is no lengthy downtime. You can rely on us to send you a replacement device immediately so that your gas measurement technology continues to work precisely and your biogas production is secured.

Which measuring devices are particularly important for my biogas plant?

Relevant measuring devices primarily include gas analyzers that measure methane (CH₄), carbon dioxide(CO₂), hydrogen sulphide (H₂S), hydrogen (H₂) and oxygen (O₂). These devices are crucial for process optimization and ensuring high gas quality as well as protecting the system.

Why should I use a system cabinet in my biogas plant?

A system cabinet offers you a space-saving and efficient solution for organizing all gas analyzers and gas coolers centrally. This simplifies maintenance and you always have an overview of your measurement technology without having to operate multiple locations.

What do terms such as process measurement technology, online measurement, gas measurement technology and gas analyzers mean in the biogas plant?

A great deal of technical knowledge is required to fully understand a biogas plant, how it works and how it is monitored. The following is a list of frequently used terms that are specifically relevant to monitoring and the associated measurement technology:

- Online measurement: An online measurement is when a measurement is carried out without the material being permanently removed from the process. At the same time, however, the measuring device is not installed directly in the process, but is connected to it via a bypass. A measurement in which material is removed from the process is referred to as an offline measurement. A measurement in which the measuring device is integrated into the process itself is referred to as an inline measurement.

- Gas measurement technology / gas analysis technology: A general umbrella term for devices that measure or detect gases, as well as for the technical methods used in these devices for measurement.

- Gas analyzers / gas detectors: Technical terms for devices that detect gases and measure concentrations. The term detector is generally used when only the presence of gases or certain threshold values are monitored. Sensor is the term used when the concentration is quantified. An analyzer refers to complete measuring systems in which detectors or sensors are installed.

- Sample gas cooler: A device that cools gas to remove moisture through condensation. This prevents the condensation of water in the gas analyzer, protects the system and increases measurement accuracy.

- Sample gas conditioning: Refers to all processes that are used to prepare a gas mixture for measurement. Gas conditioning steps relevant to biogas include, for example, desulphurization using filters and drying the gas.

- Emission measurement / emission monitoring: Refers specifically to the measurement of emissions, i.e. substances that are released into the environment. These substances must be monitored to control the concentration of pollutants and ensure that environmental standards are met.

- Condensate separator: Pneumatic components that enable gases to be dried without active cooling by filtering out and draining condensate upstream of the measuring device.

- Long-term stability: Due to various physical and electrical effects, the measured values of a gas analyzer change over time - even if the actual gas concentration does not change. Long-term stability is the key figure used to quantify this effect.

Manage Consent

We use cookies and similar technologies to store and/or access device information. With your consent, we and our partners may use this data for ads personalization, measurement, audience insights, product development, security and fraud prevention. Furthermore, Google will use your personal data, among other purposes, to deliver and personalize ads when you give consent on this site (see How Google uses data). Other providers and details on how they use your data can be found in our Cookie Policy. If you don’t consent or withdraw your consent, certain areas, features and functions may be affected. You can change or withdraw your consent anytime via the white button permanently displayed at the bottom left of your browser window.

Functional Always active

The technical storage or access is strictly necessary for the legitimate purpose of enabling the use of a specific service explicitly requested by the subscriber or user, or for the sole purpose of carrying out the transmission of a communication over an electronic communications network.

Preferences

The technical storage or access is necessary for the legitimate purpose of storing preferences that are not requested by the subscriber or user.

Statistics

The technical storage or access that is used exclusively for statistical purposes. The technical storage or access that is used exclusively for anonymous statistical purposes. Without a subpoena, voluntary compliance on the part of your Internet Service Provider, or additional records from a third party, information stored or retrieved for this purpose alone cannot usually be used to identify you.

Marketing

The technical storage or access is required to create user profiles to send advertising, or to track the user on a website or across several websites for similar marketing purposes.

Manage Consent

To provide the best experiences, we use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us to process data such as browsing behavior or unique IDs on this site. Not consenting or withdrawing consent, may adversely affect certain features and functions.

Functional Always active

The technical storage or access is strictly necessary for the legitimate purpose of enabling the use of a specific service explicitly requested by the subscriber or user, or for the sole purpose of carrying out the transmission of a communication over an electronic communications network.

Preferences

The technical storage or access is necessary for the legitimate purpose of storing preferences that are not requested by the subscriber or user.

Statistics

The technical storage or access that is used exclusively for statistical purposes. The technical storage or access that is used exclusively for anonymous statistical purposes. Without a subpoena, voluntary compliance on the part of your Internet Service Provider, or additional records from a third party, information stored or retrieved for this purpose alone cannot usually be used to identify you.

Marketing

The technical storage or access is required to create user profiles to send advertising, or to track the user on a website or across several websites for similar marketing purposes.

- ←

- Contact us Contact us

- WhatsApp us!

- Mail us!

- Call now!