NDIR - Measurement principle

Precise and economical process for infrared-active gases

The non-dispersive infrared measurement method (NDIR) is a proven and highly precise method for analyzing gases in industrial processes. It is based on the absorption of infrared radiation by certain gas components such as

The NDIR method uses infrared radiation to analyze gases based on their absorption properties. A broadband infrared signal is passed through the measuring cell, which is generated by a pulsating or continuous IR emitter.

To modulate the measurement over time, the radiation is guided through an aperture wheel.

Within the measuring cell, there is a physical interaction between the infrared rays and the molecules of the gases to be detected, such as CO₂, CH₄ or H₂S. These molecules absorb the infrared radiation in specific frequency ranges that are characteristic of each gas.

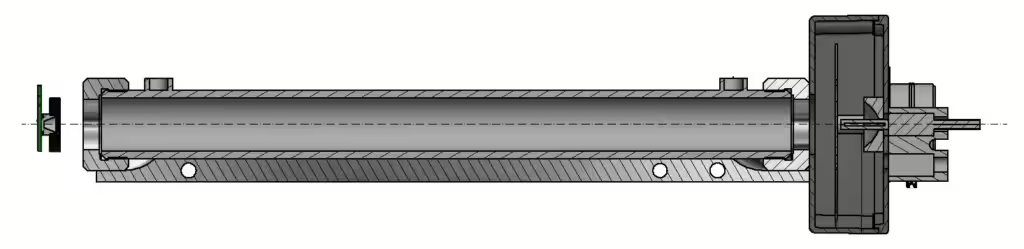

Structure of an NDIR measuring cell

Note: This is an exemplary, simplified structure

Selection of absorption frequencies

Avoid cross-sensitivities

Measurement of the gas concentration

Each gas has a unique absorption characteristic. An optical filter is used to ensure that only the target gases are detected. This filters the infrared light incident on the sensor and limits it to precisely those frequencies at which the absorption typical of the gas takes place.

In some cases, the absorption frequencies of different gases overlap. This is called cross-sensitivity. This phenomenon can be minimized by a clever selection of frequency bands. Fresenius uses sophisticated filter technologies to ensure that only the intended gases are measured.

If the gas in the measuring cell absorbs the radiation, the intensity of the signal is reduced. The level of this reduction is directly proportional to the gas concentration. The measuring device compares the reduced intensity of the light with a reference signal without absorption in order to determine the exact concentration of the gas. When analyzing several gases simultaneously in one measuring cell, several detectors are used, each with its own optical filter.

Products with NDIR technology

These products can use the NDIR method

Note: As our products are highly customizable, we offer different processes in each model, some of which can also be used in parallel.

Advantages with our NDIR technology

Automatic zero point correction

Our NDIR systems offer an innovative automatic zero point correction that ensures measurements remain reliable over long periods of time. This feature reduces the need for manual intervention and calibration by continuously monitoring the zero point and correcting it when necessary. This means you can always be

Long-term stability

The long-term stable NDIR measuring cells from Fresenius guarantee exceptional calibration stability, even under difficult operating conditions. Thanks to the

High precision

The high precision of our NDIR technology is due to Lambert-Beer’s law, which enables the exact determination of gas concentrations. Due to the specific

FAQ

What is the NDIR process?

The NDIR method (non-dispersive infrared spectroscopy) is a proven method for gas analysis based on the absorption of infrared radiation by certain gases. It is often used to measure the concentration of gases such as CO₂, CH₄ and H₂S in industrial processes.

Why should I choose the NDIR method for my process monitoring?

The NDIR method offers high precision, long-term stability and low maintenance. The automatic zero point correction and the specific filter technology ensure precise and reliable measurement results that improve your process reliability.

For which gases is the NDIR method suitable?

NDIR systems can analyze a variety of gases, including carbon dioxide (CO₂), methane (CH₄), hydrogen sulfide (H₂S) and many others. It is particularly useful for gases that absorb infrared radiation at specific wavelengths.

What are the advantages of automatic zero point correction?

The automatic zero point correction ensures that the measuring device delivers accurate measurement results over long periods of time without the need for manual calibrations. This saves time and costs, as maintenance is minimized and the system remains reliable over the long term. Read more about automatic zero point correction.

How often do NDIR systems need to be calibrated?

Thanks to the long-term stability of Fresenius NDIR measuring cells, only one annual calibration is usually required. This significantly reduces maintenance costs compared to other measuring systems.

What does cross-sensitivity mean and how is it minimized?

Cross-sensitivity occurs when different gases have similar absorption frequencies and the measurement result is distorted. Fresenius NDIR systems minimize this problem by using optical filters that only allow the specific wavelengths of the target gases to pass through. This increases the precision of the measurements.

How do difficult environmental conditions affect NDIR measuring cells?

The design of the Fresenius NDIR measuring cells is robust against temperature fluctuations and pressure changes. This means that the devices work reliably and precisely even under difficult operating conditions.

What applications are there for the NDIR process in industry?

NDIR systems are used in many industries, including:

- Biogas plants for monitoring methane production

- Power plants for emission monitoring

- Pharmaceutical and chemical industry for process control

- Environmental monitoring for the measurement of CO₂ and other greenhouse gases

What is the measurement accuracy of the NDIR method?

NDIR systems offer very high measurement accuracy, typically in the range of up to 0.1 % of the concentration of the gas to be measured. This is particularly important in processes where even the smallest deviations can have a major impact.

We use cookies and similar technologies to store and/or access device information. With your consent, we and our partners may use this data for ads personalization, measurement, audience insights, product development, security and fraud prevention. Furthermore, Google will use your personal data, among other purposes, to deliver and personalize ads when you give consent on this site (see How Google uses data). Other providers and details on how they use your data can be found in our Cookie Policy. If you don’t consent or withdraw your consent, certain areas, features and functions may be affected. You can change or withdraw your consent anytime via the white button permanently displayed at the bottom left of your browser window.

Functional Always active

Preferences

Statistics

Marketing

Functional Always active

Preferences

Statistics

Marketing

- ←

- Contact us Contact us

- WhatsApp us!

- Mail us!

- Call now!