Waste water

Monitoring, safety and efficiency for wastewater treatment plants

Wastewater treatment plants are a key pillar in the protection of our environment and the sustainable use of water resources. With reliable and precise measurement technology for operational safety, process optimization and emission measurement, we support the operation of your wastewater treatment plants in all phases – from pre-treatment to energy generation.

Our precise gas analyzers ensure maximum efficiency, safety and reliability.

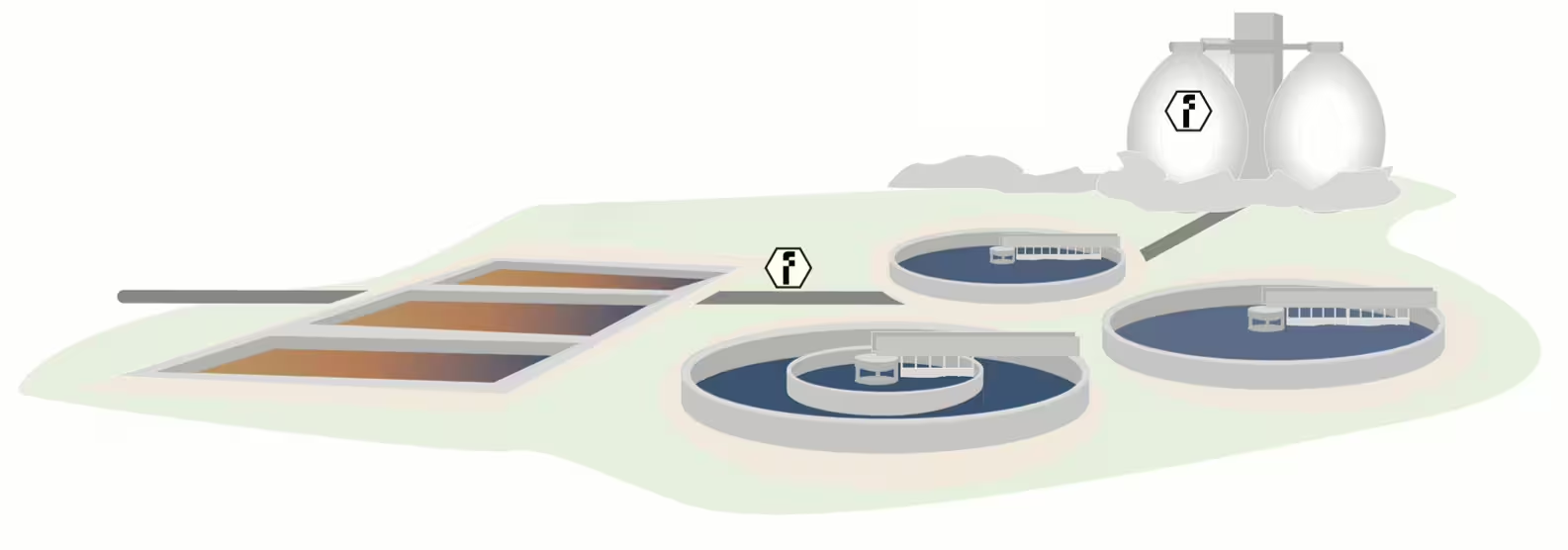

Interactive process graphic

Select a point on the graphic to find out information about the solutions for the respective gas tapping points below the graphic.

(The selection refers to the respective tapping point (eng. touchpoint) that would be suitable for your system)

Solutions for the selected tapping point:

Reliable gas monitoring is essential for the safe and efficient operation of biological treatment stages in wastewater treatment plants. Our systems continuously record all relevant gases to ensure both process safety and compliance with regulations.

Methane (CH₄) serves as an early indicator for undesirable anaerobic processes. These can occur more frequently if there is an insufficient oxygen supply. A sufficient supply of oxygen is therefore essential, as methane has a global warming potential (GWP) around 20 times higher than CO₂ and should never escape into the environment. As it is already ignitable from 4.4% by volume, continuous measurement makes a significant contribution to explosion prevention and reliably protects your system.

Carbon dioxide (CO₂) is also recorded in order to detect explosive atmospheres at an early stage and validate the methane values plausibly. This prevents process disruptions and ensures safe plant operation.

Nitrous oxide (N₂O) and ammonia (NH₃) provide information about nitrogen conversion processes. Nitrous oxide is particularly critical as a greenhouse gas with a global warming potential 265 times higher than CO₂. Our monitoring enables environmental risks to be identified in good time and regulatory requirements to be reliably met.

Oxygen (O₂) is detected above the tank using precise sensor technology to control the aeration efficiently. This saves energy and noticeably reduces operating costs without jeopardizing process stability.

Another key parameter is hydrogen sulphide (H₂S). Even low concentrations can have a toxic effect and lead to corrosion damage. Continuous H₂S measurement protects against health risks and identifies local anaerobic zones at an early stage.

With our measurement solutions, you create the basis for stable, safe and economical operation of your wastewater treatment plant - in compliance with environmental and safety standards.

In your digestion towers, anaerobic digestion produces a complex gas mixture that you can either use to generate energy or - if there is a surplus - burn via a flare. In both cases, precise gas analysis is crucial to ensure that you operate your plant efficiently, safely and in compliance with the law.

The following applies to energy recovery: the higher the methane content (CH₄), the more economical your recovery is - whether in CHPs or after processing in the gas grid. At the same time, the CO₂ content shows you how efficient your fermentation process is. With the precise measurement of hydrogen sulphide (H₂S), you can detect corrosive contamination at an early stage and replace your activated carbon filter in a targeted manner without premature maintenance or unnecessary costs. Rising hydrogen values (H₂) indicate faults in the fermentation process - so you can take countermeasures in good time. Monitoring oxygen (O₂ ) helps you to keep the anaerobic conditions in balance and minimize the risk of explosion.

If you do not utilize your gas, clean and controlled flare combustion is essential. Our solutions ensure that you achieve complete combustion of methane and thus avoid methane slip - an important contribution to climate protection. Continuous monitoring of CO and NOₓ enables you to reliably control temperature curves and combustion quality. This allows you to effortlessly meet the requirements of TA Luft and BImSchG.

Monitoring emissions such as methane (CH₄) and nitrous oxide (N₂O) is a key component of modern wastewater treatment plants in order to minimize environmental impact and meet legal requirements. These two gases have a high global warming potential, which is why their precise detection at critical points in the plant is essential. Our measurement technologies provide reliable quasi-continuous data that helps you to reduce emissions in a targeted manner and increase the efficiency of your plant.

Methane (CH₄) is released during the entire purification process. Anaerobic processes can emit methane that could enter the atmosphere unnoticed. Our technologies enable continuous monitoring of methane concentrations. This allows you to detect uncontrolled emissions and precisely control processes such as sludge retention time or aeration.

Nitrous oxide (N₂O) is often produced in the biological treatment stage during denitrification, especially in the case of inefficient operation or unexpected loads such as strong inflow variations. With our solutions, N₂O emissions can be measured directly above the basin so that adjustments such as controlling wastewater inflows or optimizing aeration can be made at an early stage. This not only helps to reduce emissions, but also to prevent system failures and ensure the stability of microbial processes.

In addition, monitoring methane and nitrous oxide emissions in exhaust air systems and chimneys is essential to ensure compliance with legal requirements and reporting obligations.

Suitable products for your system:

The ExGard is an explosion-proof gas detector specially developed for monitoring toxic and flammable gases such as methane (CH₄), carbon monoxide (CO) and oxygen (O₂). It works in critical industrial environments and ensures maximum safety.

Our gas coolers are essential components of sample gas conditioning and are used to significantly reduce moisture in gas samples. They ensure stable and reproducible measurement results by preventing condensation in sensitive measuring cells.

The Gas Analyzer 210 provides reliable and continuous measurements for demanding industrial processes. With the option of using NDIR, zirconium oxide or an electrochemical sensor, it is the perfect solution for your complex requirements.

The SmartControl 300 is a cost-effective stationary NDIR measuring device developed for monitoring threshold concentrations in gas mixtures containing solvents. It is characterized by high long-term stability and low operating costs.

The Gas Analyzer 220 is your reliable partner for the precise analysis of up to six process gases in almost any industrial environment. This multi-gas analyzer offers state-of-the-art technology to meet the highest standards of accuracy, safety and reliability.

The BioBasic Gas Analyzer is the ideal measuring device for fast and reliable online measurement in biogas plants, sewage treatment plants and landfills. Developed to measure the quality of process gases, it enables efficient process control and thus contributes to the stability and economic efficiency of your plant.

Reduce energy costs with biogas

The conversion of sewage sludge into biogas offers sewage treatment plants a good opportunity to generate energy from waste materials and at the same time reduce their own energy requirements. Sewage treatment plants are among the most energy-intensive municipal facilities, with a large proportion of the energy used for aeration and pumping.

Biogas, which consists mainly of methane (CH₄), can be fed into the gas grid after processing or used to generate electricity and heat. This not only reduces dependence on external energy sources, but also minimizes the environmental impact, as the methane is used in a controlled manner instead of escaping unused into the atmosphere as a powerful greenhouse gas.

Precise monitoring of biogas production is the key to efficiently controlling the process and optimizing the gas yield. Measured values for methane (CH₄), hydrogen sulphide (H₂S) and carbon dioxide (CO₂) provide the basis for targeted adjustments that ensure consistently high gas quality. The control of H₂S also protects infrastructure and catalysts, while the monitoring of CO₂ and pressure conditions keeps microbial processes stable.

With modern measurement technologies, wastewater treatment plants can not only increase their energy efficiency, but also reduce maintenance costs and actively control emissions. Converting sewage sludge into biogas makes operation more economical, reduces the ecological footprint and strengthens the role of the wastewater treatment plant as a sustainable energy producer.

The complete system

Our system cabinets offer you a fully integrated solution that is specially tailored to the requirements of wastewater treatment plants or biogas plants. All the important components for measuring and controlling your plant processes or monitoring your emissions are housed in a single system cabinet.

With our technology, you ensure precise emission or process monitoring that reliably detects all relevant gases such as methane (CH₄), hydrogen sulphide (H₂S) and carbon dioxide (CO₂). This is not only crucial for the safety of your systems and your employees, but also for optimizing your processes and increasing your energy yield (in the case of biogas use).

Our sophisticated service concept ensures minimal downtime and smooth maintenance. The devices can be easily removed and sent in for maintenance if required, or our experienced service team can come directly to you on site.

You can rely on German engineering skills, a proven system design and decades of experience in the field of safety and emission monitoring. Our solutions make your system more efficient, more sustainable and more economical.

Your advantages

Maximum personal protection

In addition to compliance with environmental regulations, monitoring emissions is a key component of personal protection in wastewater treatment plants. Our precise measuring systems detect toxic gases such as hydrogen sulphide (H₂S) or ammonia (NH₃), as well as flammable gases such as methane (CH₄) at an early stage.

High precision

We measure gases such as methane (CH₄), hydrogen sulphide (H₂S), carbon dioxide (CO₂), nitrous oxide (N₂O) and ammonia (NH₃) precisely and reliably. These and other measured values are crucial for optimally controlling processes, maximizing energy yield when using biogas and effectively controlling emissions. Accurate data ensures the safe, efficient and sustainable operation of your plant.

Protection of your system

By monitoring hydrogen sulphide (H₂S ), you can protect your system from harmful corrosion. This not only reduces maintenance costs, but also significantly extends the service life of your system technology. With our gas analysis devices, you can minimize expensive repairs and unnecessary downtime.

Long-term cost reduction

Our appliances are designed for a long service life and minimal maintenance. This reduces the running costs of your system. Should maintenance nevertheless be necessary, we offer you rental devices so that your system can continue to operate without interruption. Investments in our measurement technology pay off quickly – through optimized processes, reduced operating costs and higher yields.

All-round service

With our on-site service and the option to easily send in devices for maintenance, you can always be sure that the monitoring in your plant is running smoothly. Our service team is at your side so that you can concentrate on the essentials: efficient and effective operation of your wastewater treatment plant.

FAQ

Why is gas measurement technology so important in wastewater treatment plants?

Measurement technology is essential for minimizing safety risks, monitoring emissions and complying with legal requirements. Toxic and explosive gases such as hydrogen sulphide (H₂S) or methane (CH₄) can be detected through precise measurements, increasing safety for personnel and plants. Energy savings are usually realized in conjunction with a biogas plant, where the measurement data helps to control the processes in a targeted manner and maximize the energy yield.

Which gases are monitored in wastewater treatment plants?

Gases such as methane (CH₄), hydrogen sulphide (H₂S), carbon dioxide (CO₂), nitrous oxide (N₂O) and ammonia (NH₃) can be produced and monitored in wastewater treatment plants. H₂S and NH₃ in particular are often relevant as they are toxic and odorous.

Why is the monitoring of methane (CH₄) in biogas plants so important?

Methane (CH₄) is the main component of biogas and is crucial for its energy content. Precise monitoring makes this possible:

- Process optimization: Maximizing methane production by adjusting the process parameters.

- Safety: Early detection of gas accumulations and explosion risks.

- emissions: Reduction of uncontrolled methane losses, which is a greenhouse gas that is significantly harmful to the climate.

- For systems without energy generation , emissions monitoring provides the data for verification for emissions reports (e.g. EU Regulation 517/2014 / US Directive 40 CFR Part 98 (Greenhouse Gas Reporting Program)).

What role does hydrogen sulphide (H₂S) play in sewage treatment and biogas plants?

H₂S is toxic, odorous and highly corrosive. Its monitoring is important in order to:

- prevent corrosion damage to system components such as gas pipes, pumping stations and digestion towers.

- ensure safety for employees.

- Extend the service life of catalytic converters and combined heat and power plants in biogas plants, as H₂S can impair their efficiency.

How does process measurement technology contribute to the economic efficiency of a biogas plant?

Precise monitoring of the gases makes it possible to maximize the energy yield from biogas and minimize losses. This can:

- More electricity and heat can be generated from the biogas produced.

- The gas quality for feeding into the grid or further processing can be ensured.

- Maintenance and repair costs can be reduced by detecting problems at an early stage.

Which areas of the wastewater treatment plant require measurement technology?

- Pre-treatment: measurement of hydrogen sulphide (H₂S) and ammonia (NH₃) to minimize odour and toxic risks, measurement of methane (CH₄) accumulations under covers / in closed rooms, measurement of carbon dioxide (CO₂) to monitor microbiological processes.

- Biological treatment stage: Monitoring of oxygen (O₂), CO₂, CH₄, H₂S and nitrous oxide (N₂O) to optimize microbial processes, control emissions and protect against corrosion.

- Digesters: Monitoring of CH₄, H₂S, CO₂, O₂ to optimize biogas production and treatment, as well as corrosion protection of important plant components and explosion safety.

Why is emission monitoring in wastewater treatment plants important?

Wastewater treatment plants emit climate-relevant gases such as methane and nitrous oxide. Continuous emission monitoring helps:

- comply with environmental regulations and reporting obligations and reduce greenhouse gases.

- detect process deviations at an early stage.

- Improve the environmental balance of the plant.

What are the advantages of a central measuring solution in system cabinets?

Our system cabinets offer a space-saving and centralized solution in which all gas analyzers for various measuring points are integrated. The advantages are

- Increased efficiency through centralized control and analysis.

- Easy servicing thanks to removable appliances.

- High flexibility for integration into existing systems.

How does gas measurement technology contribute to the safety of a wastewater treatment plant?

Our measurement technologies are particularly crucial in closed systems, as dangerous gas accumulations can occur here. By continuously monitoring gas concentrations, such as methane (CH₄) (explosion risk) or hydrogen sulphide (H₂S) (toxic), potential hazards are detected at an early stage. This protects staff and enables preventive measures to be taken to avoid breakdowns and ensure safety.

Even open systems harbor risks: Gases can accumulate when the sewage sludge stagnates or during maintenance. Our devices monitor CH₄ in pump shafts, for example, or ammonia (NH₃) during sludge removal - and issue an alarm if limit values are exceeded.

How does measurement technology reduce emissions in biogas plants?

The precise recording of methane (CH₄), nitrous oxide (N₂O) and carbon dioxide (CO₂) supports the control of emissions and helps to comply with environmental regulations. Particularly when monitoring biological processes and in digesters, emissions monitoring is an important contribution to reducing greenhouse gases and optimizing gas quality.

Why is the measurement of nitrous oxide (N₂O) in the wastewater treatment plant relevant?

Nitrous oxide (N₂O) is often produced in the biological treatment stage by inefficient denitrification processes. It is a potent greenhouse gas that must be controlled in order to comply with reporting obligations and reduce emissions from the plant.

N₂O must be reported in accordance with the EU-E-PRTR Regulation from 10 tons/year. It is also part of the national greenhouse gas reports in accordance with the Governance Regulation (EU) 2018/1999.

In the US, wastewater treatment plants with biological nitrogen removal must report N₂O under EPA 40 CFR Part 98, Subpart II if they treat at least 50 million gallons of wastewater annually. Even without a requirement, measurement helps save energy and minimize risks for ESG reporting.

How often do sensors need to be serviced?

NDIR sensors only require annual calibration, EC sensors every 6 months. Our systems with NDIR technology offer automatic drift detection as part of the ZeroLock zero point correction and reduce downtimes.

What role does gas detection technology play in odor control?

Ammonia (NH₃) and hydrogen sulphide (H₂S) are the main causes of unpleasant odors. Real-time measurement allows you to dose chemicals (e.g. ferric chloride) in a targeted manner to reduce unpleasant odors.

We use cookies and similar technologies to store and/or access device information. With your consent, we and our partners may use this data for ads personalization, measurement, audience insights, product development, security and fraud prevention. Furthermore, Google will use your personal data, among other purposes, to deliver and personalize ads when you give consent on this site (see How Google uses data). Other providers and details on how they use your data can be found in our Cookie Policy. If you don’t consent or withdraw your consent, certain areas, features and functions may be affected. You can change or withdraw your consent anytime via the white button permanently displayed at the bottom left of your browser window.

Functional Always active

Preferences

Statistics

Marketing

Functional Always active

Preferences

Statistics

Marketing

- ←

-

Contact us

Contact us

- WhatsApp us!

- Mail us!

- Call now!